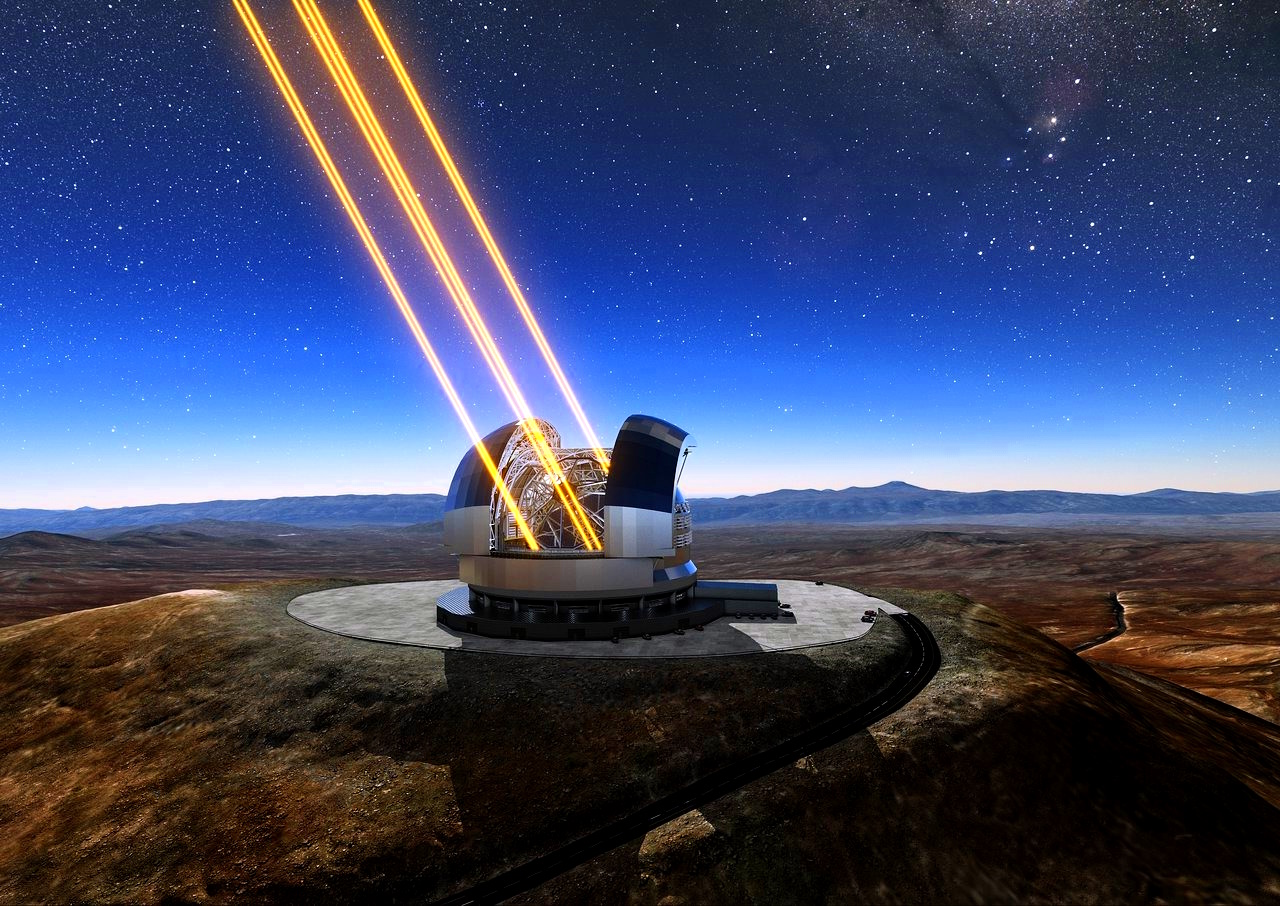

The Extremely Large Telescope (ELT) under construction in Chile’s Atacama Desert is one step closer to realization. The German company SCHOTT has produced the blank for the last segment of its main mirror.

Most powerful observatory in history

Once operational, the ELT will be the most powerful optical instrument in history. It will be able to collect 100 million times more light than the human eye and 13 times more than the largest operating optical telescopes. This will provide answers to some of the unsolved questions about our Universe. For example, how the first stars and galaxies formed. The ELT will also be able to take direct images of extrasolar planets.

All this will be possible thanks to the ELT’s gigantic 39-meter-long main mirror with a total area of 978 m² and a mass of 132 tons. It is the largest mirror ever built for a telescope.

Such a structure is too large to be made from a single piece of glass. Therefore, the ELT’s main mirror will consist of 798 hexagonal segments, with diameters of 1.5 meters and about five centimeters. An additional 133 fragments were fabricated to facilitate maintenance and re-coating of the segments after the telescope was commissioned. The European Southern Observatory also purchased 18 spare segments, bringing the total to 949.

ELT mirror manufacturing process

ELT mirror segments are created by machining blanks. They are made of ZERODUR®, a low-expansion glass-ceramic material developed by SCHOTT.

After casting, ELT segments undergo a multi-stage international path. After slow cooling and heat treatment, the surface of each blank is shaped by ultra-precise grinding at SCHOTT. The blanks are then transported to Safran Reosc in France, where each is cut into a hexagonal shape and polished to a precision of 10 nanometers across the entire optical surface. This means that the surface irregularities of the mirror will be less than one thousandth the width of a human hair.

A number of other European companies are further involved in the assembly of the segments. The Dutch VDL ETG Projects BV produces the supports; the German-French consortium FAMES is responsible for manufacturing 4,500 nanometer-precision sensors that monitor the relative position of each segment; and Germany’s Physik Instrumente is building 2,500 actuators capable of positioning segments with nanometer precision.

After polishing and assembly, each segment is sent across the ocean to ELT’s technical center at Paranal Observatory. More than 70 finished mirror fragments have already been delivered there. There, just a few kilometers from the ELT construction site, each segment is coated with a layer of silver and then placed in storage until the telescope’s main structure is ready to receive them.

At this point, the construction of the ELT has passed the equator. The new observatory is expected to see its “first light” in 2028.

According to ESO