Future colonization of the Solar System is impossible without the creation of new bases. And a possible key to their creation is inflatable modules. Mankind has been experimenting with them for a long time, but there are still questions about their functionality.

Inflatable technology on the cusp of a “boom”

Engineers have long been looking for ways to create inexpensive but reliable accommodations for living and working in space. Among the solutions that have been proposed decades ago are inflatable or folding modules.

Despite the simplicity of the idea, it was realized only in the XXI century due to the innovative work of Robert Bigelow and his team in the Las Vegas-based company Bigelow Aerospace.

The company built two unmanned free-flying expanding prototype modules that were launched into Earth orbit in 2006 and 2007, respectively, as part of the Genesis program. They are still circling the globe today. Based on NASA’s canceled TransHab program, Bigelow Aerospace was the creative hub that developed the technology for expandable space modules.

The results of their efforts are being used on the International Space Station (ISS). The Bigelow Expandable Activity Module, or BEAM for short, arrived at the ISS and remains attached to its Tranqility module until today.

Bigelow Aerospace and its innovative work on expandable modules included the use of patented extensions made from Vectran protective fabric, a stronger alternative to Kevlar. It is a high performance liquid crystal polymer fiber that has better properties compared to Kevlar. Although the company ceased to exist back in 2020, its developments are still in use today.

Folding constructions

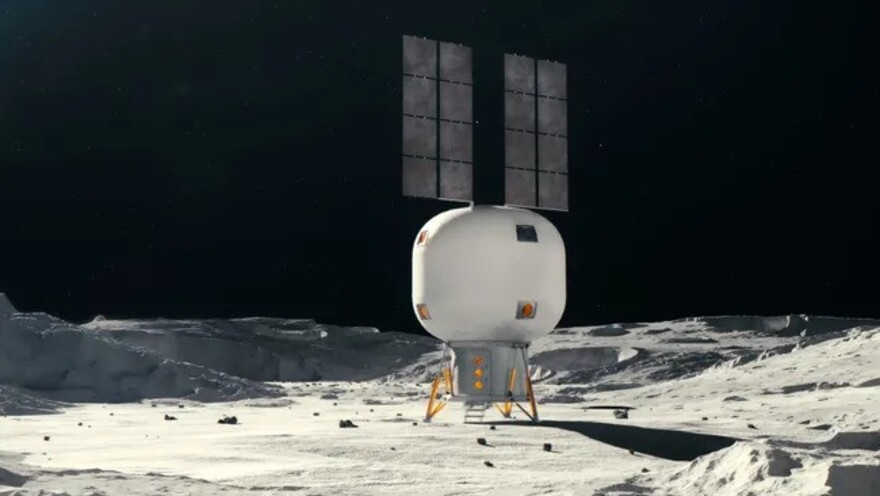

There are several leading firms working on expandable space structures these days, such as new startup Max Space, which is working on inflatable living habitats for Earth orbit, the moon and Mars.

Sierra Space is also involved in this project, developing a habitat called the Large Integrated Flexible Environment (LIFE). In a similar way, Lockheed Martin is testing concepts for inflatable structures that have advantages over their all-metal counterparts.

Each group examines the promising potential of the expandable technology. And each company has its own “secret sauce” embedded in their products.

Max Space Megastructures

“The future of space is limited by space,” explained Maxim de Jong, co-founder of Max Space, based in Jacksonville, Florida, with design offices in Vancouver, Canada.

This is not the first time de Jong has worked with expandable space structures; he designed the pressurized hulls of Bigelow’s Genesis 1 and 2, the first spacecraft in orbit to successfully utilize a high volume inflatable architecture to withstand high loads.

“We are gearing up to fly our maiden mission in 2026,” de Jong told Space.com. As part of the process, the team recently successfully tested a new shield design to protect against space debris. “That is a real progress discriminator, given how challenging, in terms of design, time and cost, debris shield development is.” de Jong said.

Max Space’s goal is to create a family of scalable space habitats ranging from 20 m3 to 100 m3 and up to 1000 m3 by 2030. There is the potential to scale up to 10,000 cubic meters (350,000 cubic feet) of “megastructures” that could be launched into space in a single flight, using SpaceX’s Starship or Blue Origin’s New Glenn megarocket, “as soon as they are launched.”

Greater volume and less mass

Lockheed Martin experts explain that inflatable structures provide more volume with less mass. This means that large habitable volumes could be launched into space, hidden inside reasonably sized payload fairings.

The Pathfinder unit, intended for use as an airlock, has recently undergone leak and depressurization testing. The airlock structure underwent several cycles to assess the creep factors of the Vectran material from which it is made.

Lockheed Martin, in partnership with NASA’s Marshall Space Flight Center in Alabama, initiated a 100-hour “creep” test, during which a block of soft material was pressurized to a certain percentage of the ultimate rupture pressure of 285 pounds per square inch (PSI) and held at that pressure until no rupture occurred as a result of creep. Creep is the permanent deformation of a material.

Duong and his colleagues are taking a closer look at large inflatable habitats for use on the Moon and Mars, as well as in low Earth orbit.

Creating modules at Sierra Space

Shawn Buckley is vice president of space direction and space infrastructure at Sierra Space in Louisville, Colorado. Previously, he was a key BEAM architect at Bigelow Aerospace.

Now, Buckley and his team at Sierra Space are engaged in work on the LIFE habitat, developing a product evolution plan that could lead to a 5,000-cubic-meter module that expands to more than 22 meters long and 19 meters in diameter.

The first product on Sierra Space’s roadmap is a large three-story expanding structure 27 feet (more than 8 m) in diameter. It could be launched into Earth orbit by a regular rocket equipped to accommodate four astronauts, with a “space” room for science experiments, a gym, a medical center and a special greenhouse to grow food for researchers on long missions.

“In a little over 2.5 years, we have been able to build and test seven articles, and now going into our eighth. We’re moving at a fast rate,” Buckley told Space.com. “The technology is really gaining momentum, and we’re moving very quickly.”

Purpose of inflatable systems

Inflatable home-building systems “have a role as one tool in our toolkit for expanding, so to speak, human spaceflight for new markets and missions,” says Brent Sherwood, a famous space architect and space industry executive at the American Institute of Aeronautics. He formerly served as senior vice president of space systems development for Blue Origin.

“Like all tools, they’re best used for a niche purpose,” Sherwood Sherwood told Space.com. Expandable structures may find particular use as “connector elements,” he added. “For example, on the lunar surface, fairly soon we will need physically compliant ways of connecting separate habitat modules,” Sherwood said.

“Compliant means accommodating different floor levels — say, from a lander to a pressurized rover — imprecise surface positioning, such as in early base construction, and thermal expansion and contraction due to lunar day/night cycles,” Sherwood said.

According to Sherwood, a little compliance can greatly simplify the overall system architecture. “So it may be that one of the best uses is comparatively small connector elements rather than the goal of ‘making big modules bigger,” he said.

“Eventually, we will have to learn how to fabricate super-big pressure vessels in space, but we have a lot of market growth and validation to do between now and then,” Sherwood summarized.

Provided by www.space.com