Augmented reality is the technology of superimposing computer-generated pictures on what a person actually sees. NASA engineers have been using it for some time to assemble the Roman space telescope more accurately and quickly.

Augmented reality technologies help in design

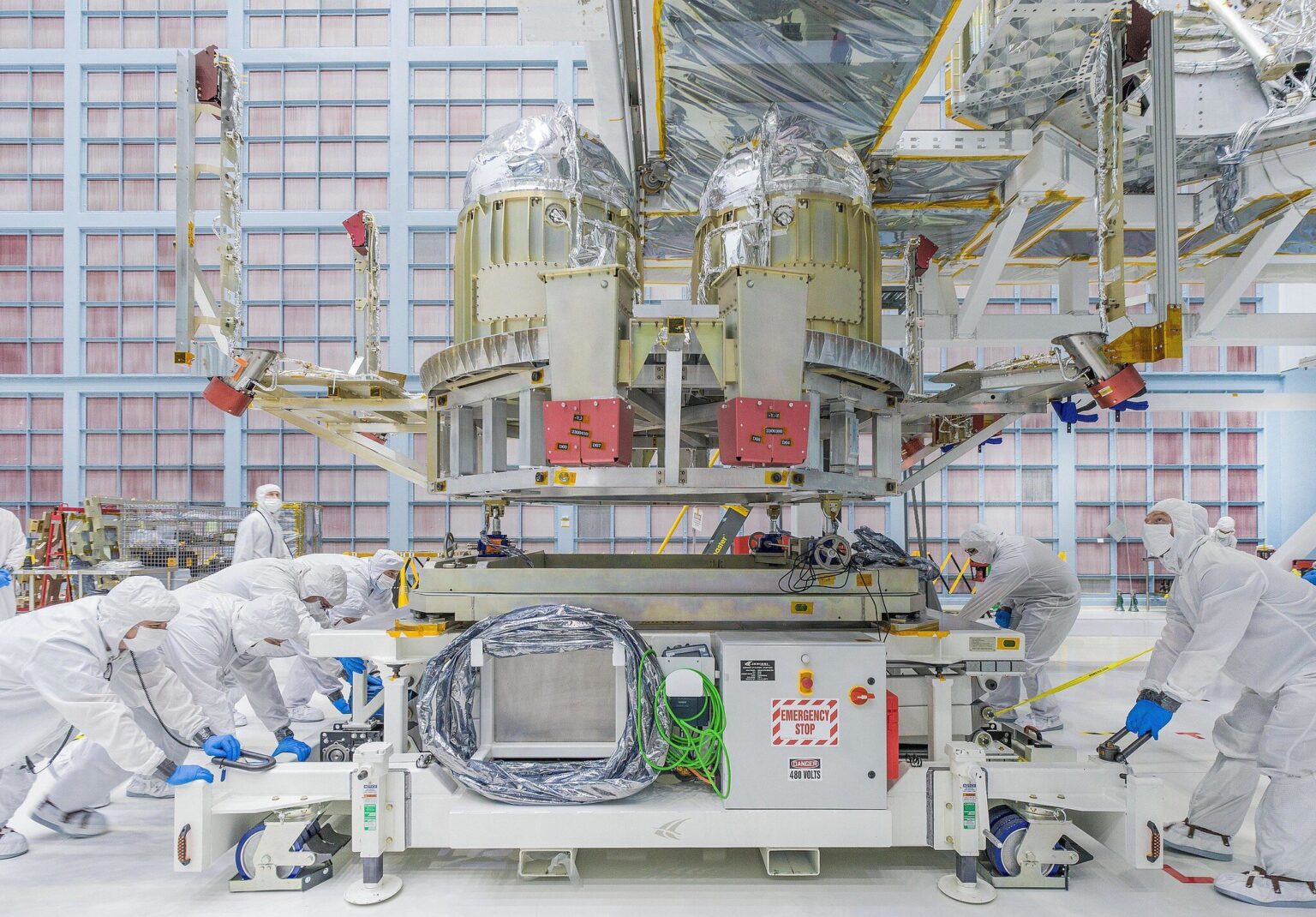

Technicians armed with advanced measurement equipment, augmented reality headsets and QR codes virtually checked the fit of some of the Nancy Roman Space Telescope structures before building or moving them around the facilities at NASA’s Goddard Space Flight Center in Greenbelt, Maryland.

“We’ve been able to place sensors, mounting interfaces, and other spacecraft hardware in 3D space faster and more accurately than previous techniques,” said NASA Goddard engineer Ron Glenn. “That could be a huge benefit to any program’s cost and schedule.”

Projecting digital models onto the real world allows technicians to align details and look for potential problems. The augmented reality display also allows you to position parts for assembly with accuracy to thousandths of a centimeter.

Using NASA’s internal research and development program, Glenn said his team continued to find new ways to improve how the agency built spacecraft using augmented reality technology in a project that helped build a space telescope at NASA’s Goddard Space Center.

How augmented reality works

Glenn said the team had accomplished much more than they initially aimed to prove. The original goal of the project was to develop improved assembly solutions using augmented reality and see if engineers could save valuable time. However, they were able to accomplish much more than that.

For example, experts used a robotic arm for precise measurements and 3D laser scanning to map the telescope’s intricate wiring and the volume inside the spacecraft’s structure.

“Manipulating the virtual model of Roman’s propulsion assembly into that frame, we found places where it interfered with the existing wiring harness,” said team engineer Eric Brune. “Adjusting the propulsion assembly before building it allowed the mission to avoid costly and time-consuming delays.”

The Roman telescope’s propulsion system was successfully integrated earlier this year. Given the time it takes to design, build, move, redesign and rebuild, Brune says their work has saved engineers and technicians many workdays.

Combining technology with augmented reality

“We have identified many additional benefits to these combinations of technologies,” said team engineer Aaron Sanford.

These technologies allow 3D designs of parts and assemblies to be shared or virtually transferred from remote locations. They also make trial runs of moving and installing structures possible and help to take accurate measurements once the parts are ready to compare with other projects.

The addition of a precision laser tracker can also eliminate the need to create complex physical templates to ensure components are accurately mounted in precise positions and orientations. Even moments such as a technician’s ability to physically reach inside a structure to turn a bolt or manipulate a part can be worked out in augmented reality before construction begins.

During construction, an engineer wearing a headset can retrieve vital information, such as torque specifications for individual bolts, with a hand gesture. In fact, a technician can accomplish this without having to stop and look for information on another device or in paper documents.

According to phys.org