Right now, in Lviv, the construction of a new school building is underway. It may seem like a fairly ordinary event, but only until you delve into the details. The thing is, the school is being constructed with the help of a 3D printer. This technology, which not long ago seemed fantastical, is capable of not only aiding in the reconstruction of war-damaged Ukrainian infrastructure but also, in the future, realizing humanity’s ancient dream of conquering Mars.

Basics of 3D Printing

3D printing is performed using computer numerical control (CNC) machines. In simplified terms, it works like this: the printer deposits material at specified points according to the 3D design programmed into it. Typically, some liquid or paste-like substance (often plastic) is used as the building material, which then solidifies quickly. However, modern printers can also work with ceramics, concrete, and even metals.

Without going into technical details, it should be noted that there is a vast variety of 3D printers today, each employing its own printing technology. Furthermore, they vary greatly in size. Standard desktop 3D printers can be compared in size to traditional paper printers, while the largest industrial printers occupy entire rooms.

3D Printers in the Service of Space Companies

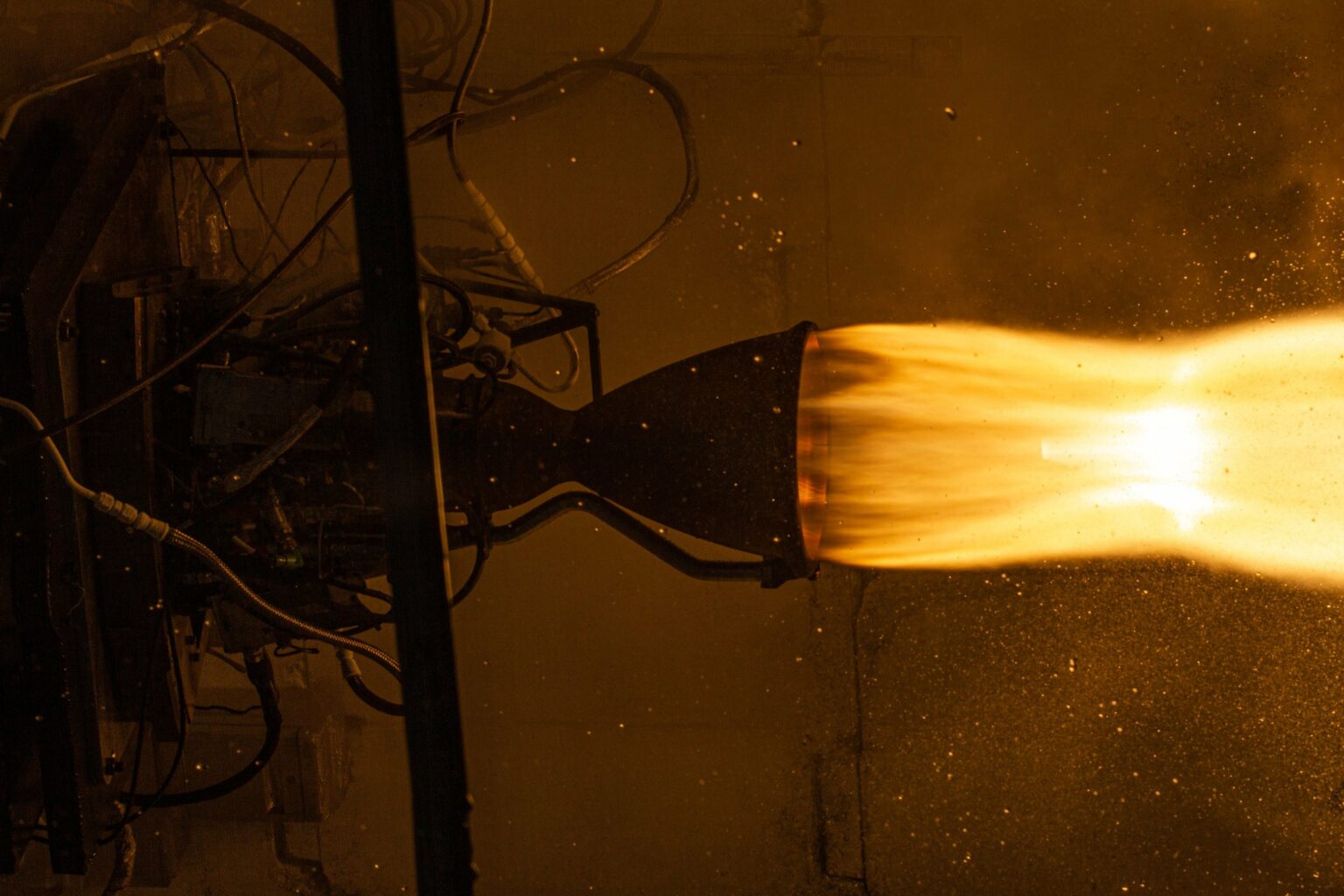

With each passing year, 3D printing is being increasingly utilized in the aerospace industry. One of the pioneers in this field is the American-New Zealand company Rocket Lab. Nearly all the components of Rocket Lab’s Electron rocket engines are 3D-printed. According to the company, this approach has saved both time and money compared to manufacturing propulsion systems using traditional methods.

Rocket Lab’s example has prompted other aerospace companies to actively embrace 3D printing. SpaceX, for instance, employs 3D printing in the production of various components for the Falcon 9 rockets and Dragon spacecraft. Airbus plans to send the first metal 3D printer to the International Space Station (ISS) this year. Using it, the company hopes to manufacture satellite components directly in orbit.

However, the company that has taken this concept to the next level is Relativity Space, which has set the goal of creating rockets that will be entirely 3D-printed. According to the designers’ plans, this innovation will significantly accelerate the rocket construction process, thereby reducing their cost. To achieve this, the company has acquired the world’s largest metal 3D printer.

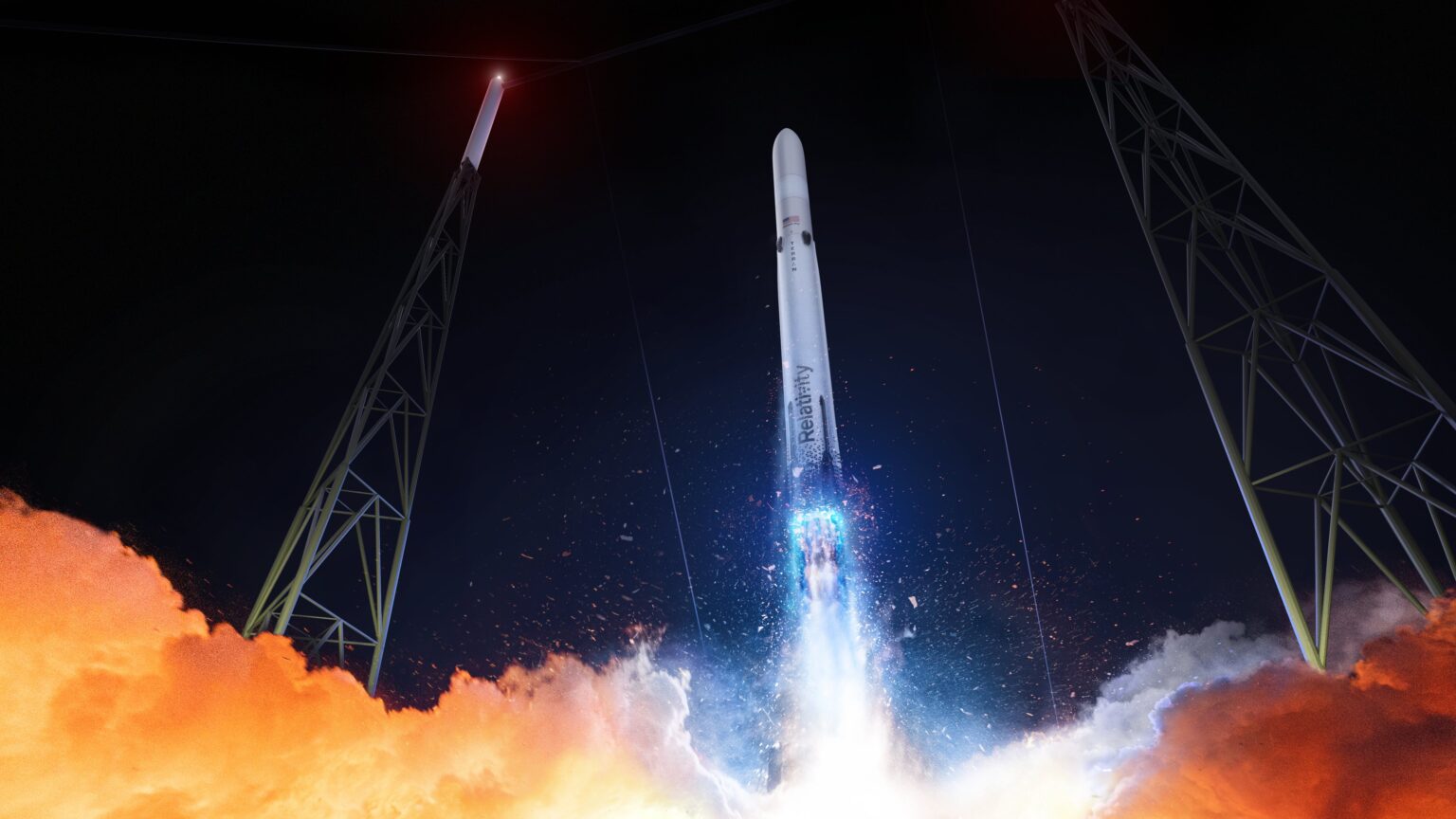

In spring 2023, Relativity successfully launched the Terran 1 rocket, 85% of which was 3D-printed. Unfortunately, due to an anomaly during the operation of the second-stage, it lacked the velocity to reach orbit. Nonetheless, Relativity is pleased with the flight results. Terran 1 successfully surpassed the Max-Q stage, the point at which the rocket experiences maximum aerodynamic stress and undergoes the highest strain. According to the company’s leaders, this demonstrates that a 3D-printed rocket, in terms of structural integrity, is on par with its traditional counterparts.

Currently, Relativity is focusing its efforts on the development of a more powerful rocket, Terran R. Its debut is planned for 2026, and it is intended to embark on the first-ever private mission to Mars in history.

From a school in Ukraine to Martian settlements

Since 3D printers do not have any fundamental limitations as for the size of the objects they produce, many engineers have long considered using them for construction. And this is quite understandable. Due to the relative simplicity of their design, construction of structures is a time-consuming process that requires significant time investment. 3D printing, on the other hand (at least in theory), offers the potential to significantly speed up this process. It is needless to explain how relevant fast construction is for our country in times of war.

Currently, this concept is being tested in Lviv. They are constructing a new single-story building for School No. 23. The project is initiated by the Team4UA humanitarian foundation, with the implementation being carried out by the Danish 3D printing company Cobod and the construction company 3DCP Group.

The new building will accommodate up to 100 students. Currently, the construction workers are nearing the completion of the first half of the building. Using a 3D printer, they have already erected a 3.5-meter printed wall, which took only two weeks. It is planned that the building will welcome its first students in January 2024.

According to Jean-Christophe Boni, the founder of Team4UA, the application of 3D printing technology allows for constructing buildings 10 times faster than traditional construction. The actual construction of walls (i.e., the work performed by the printer itself) takes no more than 80 hours. However, the entire construction process takes 4 to 5 weeks. This is due to the necessity of carrying out a series of preparatory operations preceding the printing. These include the installation and calibration of the printer along the printing trajectory, as well as the creation of an optimal concrete mixture for the specific region.

We win in terms of speed. The main idea of applying this technology in Ukraine is to construct buildings at a cost equivalent to traditional construction but much faster, which will help rapidly rebuild the devastated regions in the future.

Jean-Christophe Boni

According to Jean-Christophe Boni, the founder of Team4UA, the foundation also plans to open a training center in Ukraine for learning to work with 3D printers in the near future. This will contribute to the faster restoration of our country’s infrastructure.

In the future, 3D construction will likely find application in space as well. If humanity wants to settle on the Moon and Mars, it will need to build permanent settlements there. However, if we were to transport construction materials from Earth, it would significantly increase the costs of construction, which may not be feasible for any economy.

This is where 3D printing comes in handy. Instead of bringing a large quantity of equipment and materials, colonists will only need to take a few printers and “print” everything they need on-site. Research has shown that it is entirely feasible to manufacture monolithic bricks from lunar regolith using a 3D printer. The same applies to Martian construction.

It is also worth noting that modern 3D printers are capable of manufacturing complex structures composed of multiple materials and containing electronic components. This means that space explorers can use them not only for building their houses but also for repairing equipment and creating various mechanisms and machines. And who knows? Perhaps a part of the foundation for this space future is being laid right now in the form of a school in Lviv.